Round springs, due to their helical geometry, are more difficult to strengthen than flat-surfaced leaf springs. In addition, the strengthening effect of the cross section of the circular spring must be strictly evaluated, so as to fully understand the resistance of the circular spring to fatigue fracture.

The round springs are individually fed into the shot blasting chamber through a continuous conveyor chain system, and a set of parallel rollers are installed in the shot blasting chamber. At the same time of strengthening, the rollers keep rolling, which drives the round springs to move forward while rotating. This way of rotation allows the high-speed pellet flow to pass between the rings of the circular spring and hit the metal surface of the inner ring, where the stress of the circular spring is most concentrated.

For applications with high throughput requirements, an intensified device capable of spraying two round springs at the same time can be selected. The latest research and development results are based on the original shot blasting equipment, combined with multiple nozzles for more targeted and concentrated shot peening on the specific area of the circular spring (stress concentration pleasure).

Leaf spring strengthening can utilize a continuous pass-through shot blasting equipment to strengthen the leaf springs individually one by one, exposing the geometric concave surface of the leaf spring to the high velocity shot stream. A typical model includes a throwing head for projecting the top of the leaf spring, a throwing head on the side, and spraying the left and right sides of the leaf spring at the same time.

The standard leaf spring strengthening equipment has a passing speed of 10 feet per minute. If a higher production speed is required, the number of throwing heads can be increased and the motor frequency can be adjusted. Under operating conditions, leaf springs are repeatedly subjected to unidirectional bending stress and are therefore sometimes stressed. In the strengthening process, it simulates the situation that the leaf spring will be "stressed" in the future use process, and it is shot peened while applying a "static stress" in the direction of the load. After strengthening, the applied static stress is released. Experiments have shown that stress strengthening can further extend the service life of the leaf spring than conventional strengthening.

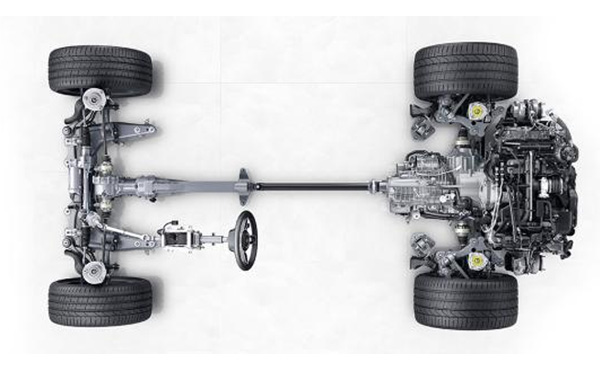

The suspension spring is strengthened, thanks to the high-stress lightweight design, the weight of the suspension spring has been greatly reduced in recent years, and the stress of the suspension spring of the new model is more than 1000Mpa is very common. The service of the spring under such high stress has exceeded the limit that the material can bear, so it must be supplemented by other strengthening methods (such as blasting/shot peening).

The main engine manufacturer adopts very strict test standards for automobile suspension springs. The longest test period is as long as 70 days (10 weeks). It should be the suspension springs that work under high stress conditions. Once the surface is subjected to stress corrosion That is, corrosion fatigue failure occurs, and if the broken spring port punctures the tire, it may cause major safety and personal accidents.

Blasting/shot peening is the most effective way to strengthen suspension springs. The fatigue life of high-stress springs can be increased by more than 5 times after proper shot peening. At present, most of the blasting/shot peening of suspension springs use steel wire cutting shots, and many times in the process Shot peening (different shot diameters) is commonly used. The compressive stress intensity and depth of the spring surface are important indicators to measure the shot peening effect. The surface stress of good shot peening is at least -600Mpa, and it can reach -800Mpa at 50um from the surface. The surface compressive stress of the stress shot peening spring can reach -800Mpa or more, and it can reach -1200Mpa at 50um from the surface.

.jpg)