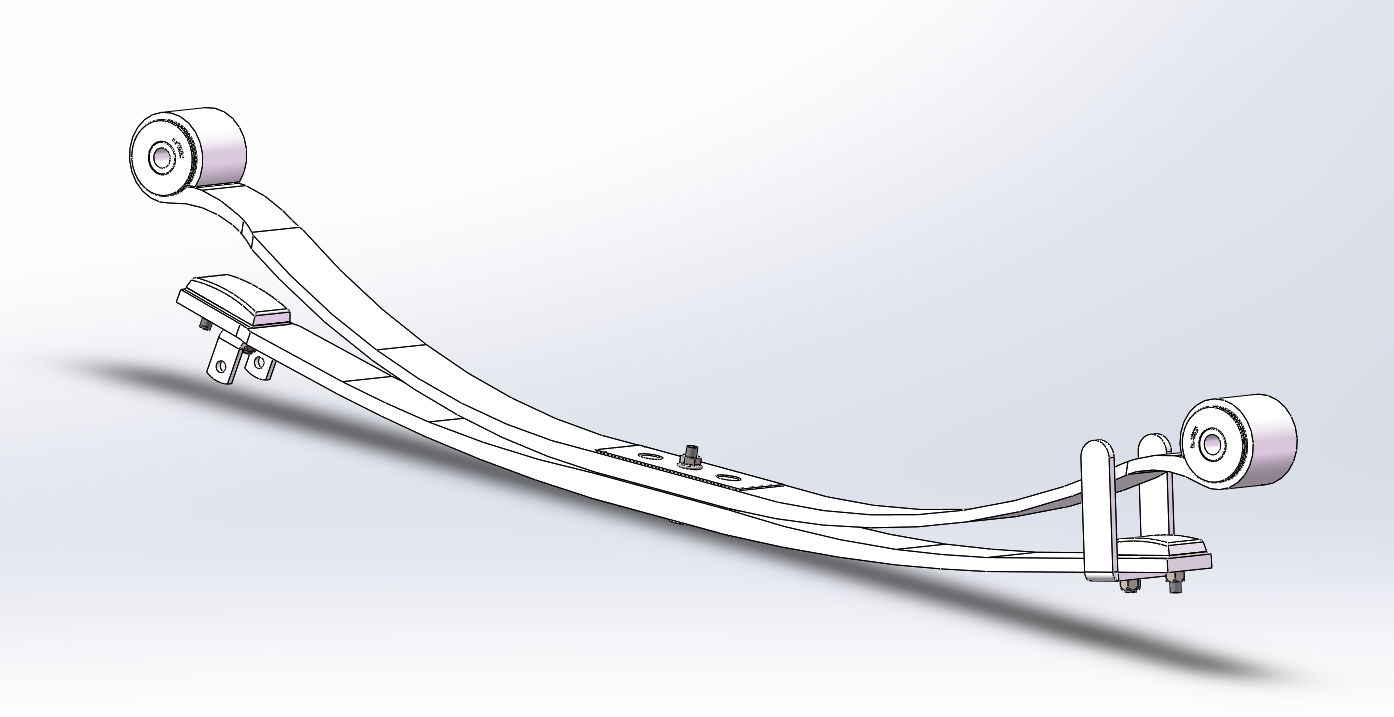

Leaf spring , the flat rectangular steel plate is curved, and the chassis spring is stacked with several pieces. One end is installed on the hanger with the tip, and the other end is connected to the girder with the lifting lug, so that the spring can be expanded and expanded. It is suitable for some hard off-road vehicles and medium and large cargo trucks with non-load-bearing bodies. Spring plate commonly used grades are 65Mn, 60Si2Mn, 50CrVA, etc., the general specification is between 1 and 30 mm. The domestic origin is Angang, Baosteel and so on. There are annealed and non-annealed states.

Leaf spring is a special steel, mainly used to make springs and other mechanical parts, these parts require high elasticity and high strength. The raw material of the spring plate can be stainless steel, carbon steel or alloy steel. Carbon steel such as 65#, 70#, 65Mn, 82B, 72A, 72B, etc., known for its low plasticity, strong elasticity and strong stress resistance, suitable for the manufacture of Simmons beds, automobiles and other cushions, mechanical equipment, stationery power tools, sporting goods, torsion springs, tensile springs and electrical equipment and other fields. Alloy spring steel needs to have high yield point, high yield ratio, good elastic limit and fatigue resistance to ensure that the spring can withstand large loads and maintain sufficient elastic deformation capacity in long-term use. In addition, alloy spring steel should also have a certain degree of plasticity and toughness, a certain degree of hardenability, not easy to decarbonize and not easy to overheat, some special types of springs also need heat resistance, corrosion resistance or to maintain good elasticity over a long period of time.

Leaf spring hardness value range Spring type and use: The standard should determine the corresponding hardness value range according to the spring type and use. For example, the hardness requirements of automotive suspension springs are relatively high, while the hardness requirements of small springs used in precision instruments may be relatively low. Technical requirements: The standard should consider the design requirements of the spring, manufacturing process and product performance needs, and reasonably set the hardness range to ensure that the spring is not easy to deform, fatigue fracture and other industrial practices in use: the standard can refer to the actual production experience of the bomb tube manufacturing industry combined with the hardness indicators of various spring materials to ensure the scientific and operability of the standard.