Leaf spring is the simplest and most commonly used load bearing component of commercial vehicle suspension structure, even if many models are matched with air suspension, but the front axle of the vehicle is still using leaf spring. Usually, everyone's cognition of the plate spring is multi-blade spring and less blade spring, multi-blade spring bearing capacity is strong, and the cab of the vehicle is too bumpy when it is driving without load; Less spring light weight, better vibration damping. In fact, in addition to the number, the knowledge inside the spring is very much, this article introduces some knowledge you do not understand the spring, to discuss the future development trend of the spring.

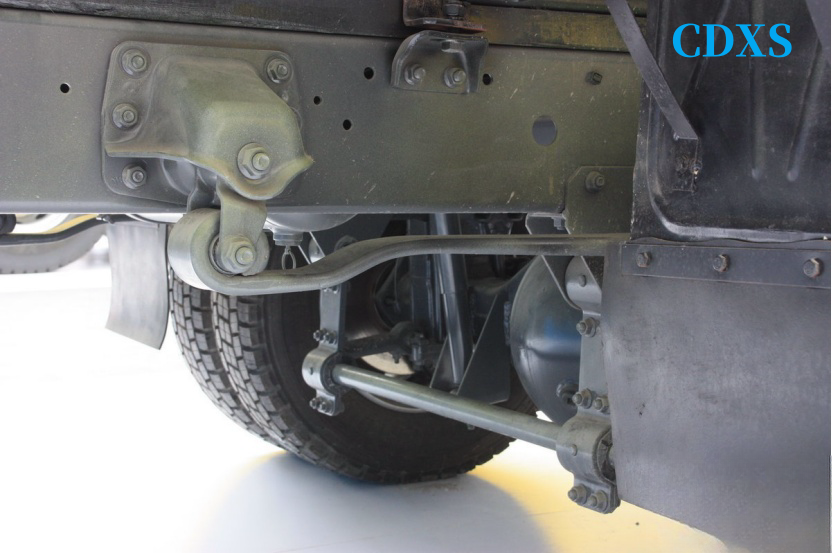

First, a single spring. As long as speaking of "single spring", many people's first reaction is the safety problem, once the broken car is destroyed. In fact, the single spring has been applied in Europe for many years, such as the front axle of the MAN TGX tractor has always used a single spring, and the rear axle of the Duff card also uses a single spring, which has the same vibration reduction effect as the air suspension. The major commercial vehicle companies in Europe have fully considered the safety issue after fracture when designing and applying single spring. The secret is to make an S-bend at the back end of the single spring, the thickness of this S-bend is about 10% thinner than the other positions, and it is the weakest point of the entire spring, and once the fracture occurs, it must be this position. The front lifting lug of the plate spring mainly plays the role of bearing, thrust and guiding, and the rear lifting lug adopts the rotating structure to mainly play the bearing role, and the thrust and guiding roles can be ignored. Assuming that the fracture occurs at the S-bend, the limit block above the middle of the spring will hold the spring to continue to play the bearing role. Since the front of the plate spring is not broken, the front lifting lug can play the role of thrust and steering, and the vehicle can still run normally. As long as the driver handles the emergency properly, brake slowly and pull over immediately, there will be no major traffic accidents.

At present, many domestic enterprises are studying the single spring, its weight can be reduced by about 30% than the two springs, due to customer concerns about the safety performance of the single spring, so there has been no commercial promotion. Special through this article for science: single spring is safe!

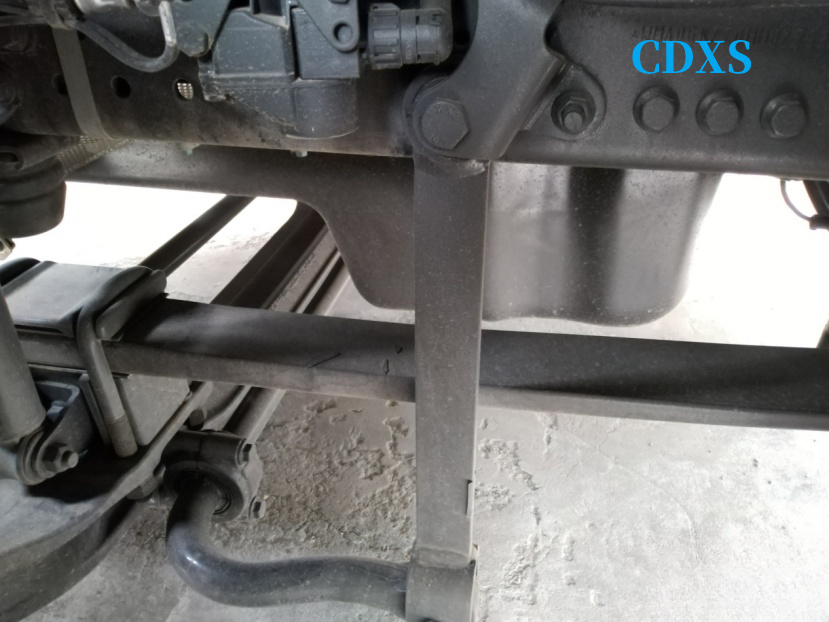

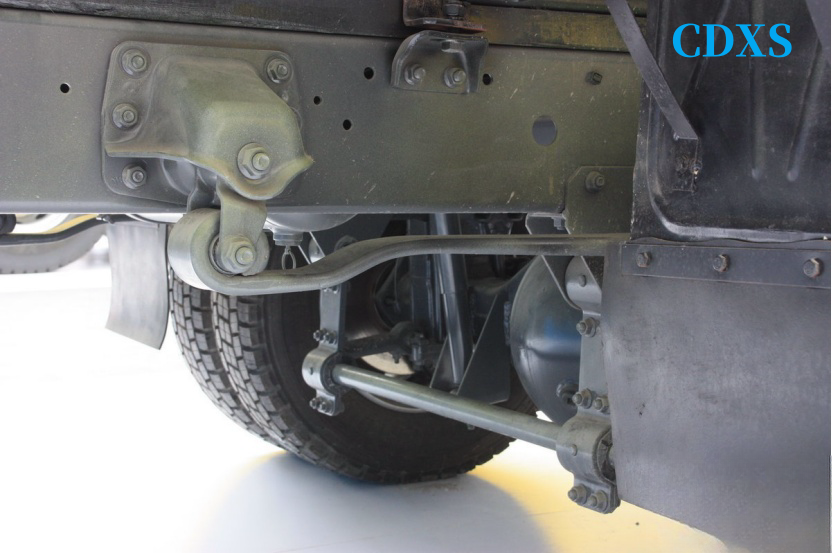

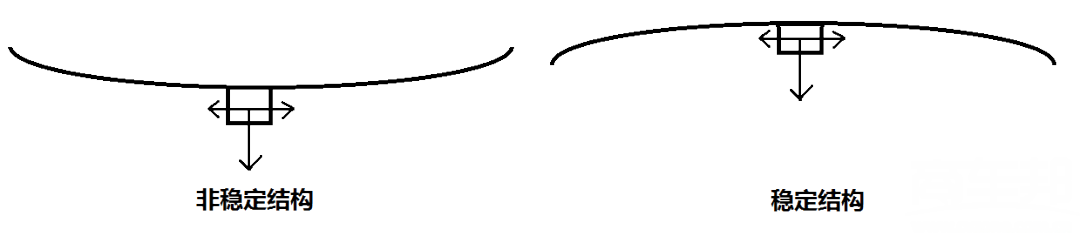

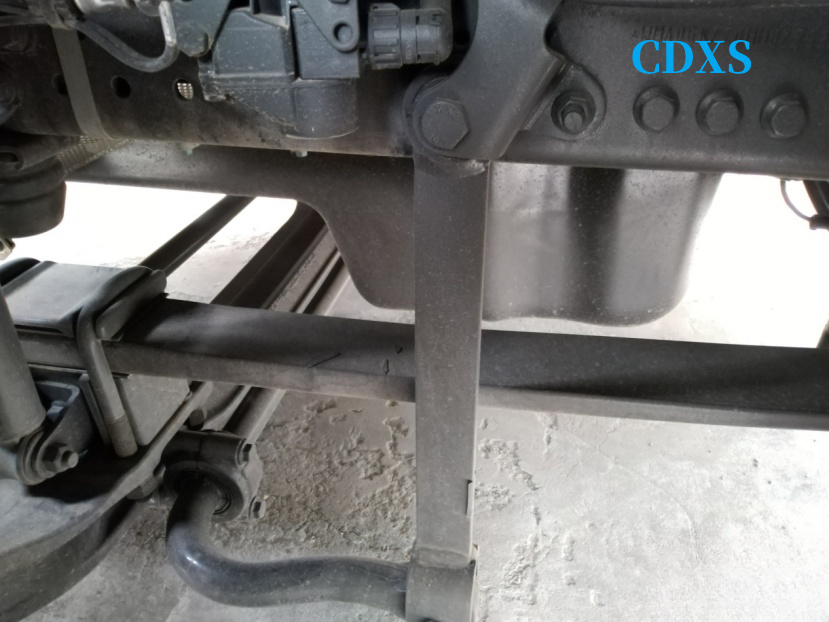

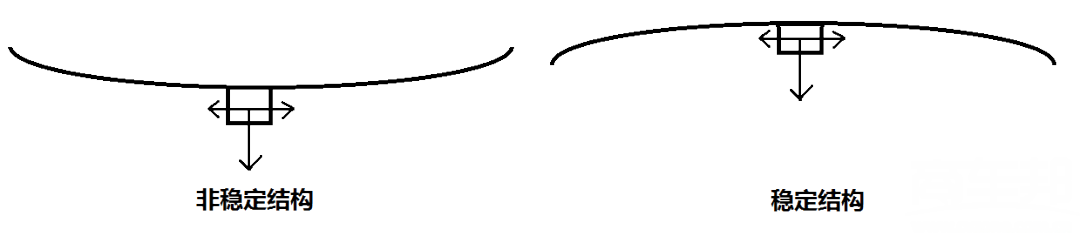

Second, reverse bow spring. In China's commercial vehicle industry, the plate spring is the lower arc, the position of the front and rear lifting lugs is high, and the position of the middle and the axle is low. In everyone's consciousness: once the plate spring is flattened, it is considered to have reached the limit of the load of the plate spring, and the backbow (the position of the middle is higher than the position of the front and back lifting lug) is considered to be about to break. In fact, this perception is wrong. In Europe, many heavy truck types use anti-bow spring, the spring is flat when no load, and the spring appears anti-bow when heavy load. In terms of design theory, assuming that the spring and the riding bolt of the front bridge are removed, the backbow design of the spring is also a stable structure, which can prevent serious deformation of the spring S and the front and back movement of the axle during emergency braking, so as to prevent the phenomenon of braking deviation of the vehicle.

Another advantage of the spring backarch design is that it can improve the ground clearance of the front axle. The front bridge of the truck in China is a ladder bridge, the middle is low and the two ends are high, and the front bridge becomes the place with the smallest clearance from the ground. At present, Mercedes-Benz Arcos engineering vehicle adopts the design scheme of "straight beam bridge + reverse bow plate spring", and the ground clearance of its front bridge has reached 380mm.

Since the processing difficulty and cost of the reverse bow spring have not increased, and the brake deviation can be solved and the ground clearance can be increased, with the design and research of the reverse bow spring carried out by many domestic commercial vehicle enterprises, it is believed that the future reverse bow spring will also become the mainstream of the industry.

Third, 100mm wide plate spring. The most effective way to reduce the weight of the spring, increase the bearing capacity of the spring, and improve the damping effect of the spring is to increase the width of the spring, such as: The rear axle of Mercedes-Benz Arcos engineering vehicle uses four plates with variable section, and its bearing capacity is equivalent to the multi-plate springs (10-13) of domestic heavy truck engineering vehicles, the reason is that the width of the plate spring reaches 100mm, while the mainstream width of the domestic plate spring is 80mm and 90mm. The lateral stiffness of the wide plate spring also increases synchronously, and the plate spring is needed to bear the centripetal force during the turning process of the vehicle, so it will play an important role in the use of the engineering vehicle with more turns. For the same thickness of the spring, the weight of 100mm is 11% higher than that of the 90mm wide spring, and the carrying capacity is 11% higher. If the 90mm spring wants to achieve the same carrying capacity of the 100mm spring, it is necessary to add a spring, and its weight is increased by about 20%.

But the spring width is not you want to increase can increase, the current heavy truck frame is constantly widening, increasing from 800mm to 850mm, and even individual companies have reached 870mm, which claims: wide frame is conducive to improving the anti-roll ability of the vehicle. This statement is difficult to establish, frame widening is "more harm than good", because the width of the vehicle is fixed, tire width is fixed, can only compress the suspension space, then the spring can not be installed 100mm wide spring, can not use 315 wide tires (the current domestic mainstream is 295 tires), anti-roll ability did not improve too much, but also affected other performance. With the continuous improvement of China's commercial vehicle design capabilities, 100mm wide plate springs will become the future development trend.

.png)

.png)

.png)