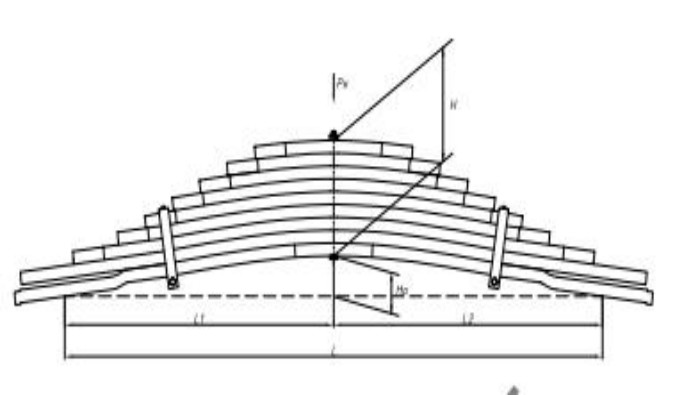

1. Multi-leaf spring suspension: common in heavy-duty vehicles, it is composed of multiple reeds with different lengths and uniform widths, usually more than 5 pieces. The length of the reeds becomes longer from bottom to top, and the bottom reed is the shortest, thus forming an inverted triangle, which makes full use of the force principle of the triangle. In addition, the number of reeds is closely related to the load-bearing capacity. The more the number of reeds and the higher the thickness, the stronger the rigidity of the reeds and the higher the load-bearing capacity. Of course, the weight of the reeds should not be underestimated.

Although the multi-leaf spring suspension has a large number of pieces, the structure is simple and the maintenance cost is low, because it is rare for the multi-leaf spring to be completely wiped out during use, and often only the damaged reed needs to be replaced separately. However, when the multi-leaf springs are used for a long time, they will produce abnormal noise due to mutual friction, and the weakened rigidity will affect the formal balance of the vehicle.

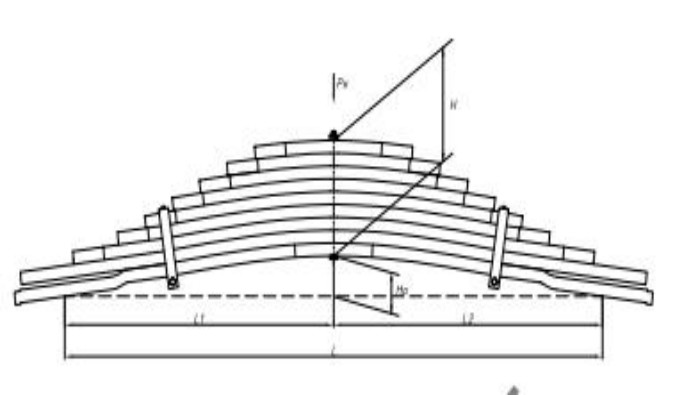

2. Less-leaf spring suspension:

The less-leaf spring is composed of reeds with thin ends, thick middle, equal width, and equal length. Therefore, the cross-sectional area of the steel plate of the less-leaf spring changes more, and the rolling process is more complicated. The price will be higher than that of the multi-leaf spring. The ordinary steel sheet is more expensive.

Compared with multi-leaf springs, the load-bearing capacity of less-leaf springs is weakened to a certain extent, but at the same time its own weight will also be reduced. According to relevant data, under the same bearing capacity, less-leaf springs can reduce 30%-40% than multi-leaf springs. % by weight.

In addition to reducing the weight of the vehicle, the noise generated by the friction of fewer leaf springs is also smaller, and the driving comfort of the vehicle has also been improved to a certain extent. In the environment of standard-load transportation, less leaf springs have become the most common type. suspension structure.